Solar panels look simple from the outside glass, frame, sunlight, power. But anyone who operates or maintains a solar system knows one quiet truth: dirty panels lose performance. Dust, bird droppings, pollen, pollution residue, salt spray, and industrial fallout slowly reduce output. Cleaning matters. How you clean matters even more.

Anúncios

This guide focuses on solar panel cleaning chemicals what works, what doesn’t, what research actually says, and how to choose suppliers responsibly. Everything here follows verified technical guidance, manufacturer recommendations, and published research trends. No exaggerated claims. No unsafe shortcuts.

Why Solar Panel Cleaning Is Not Optional

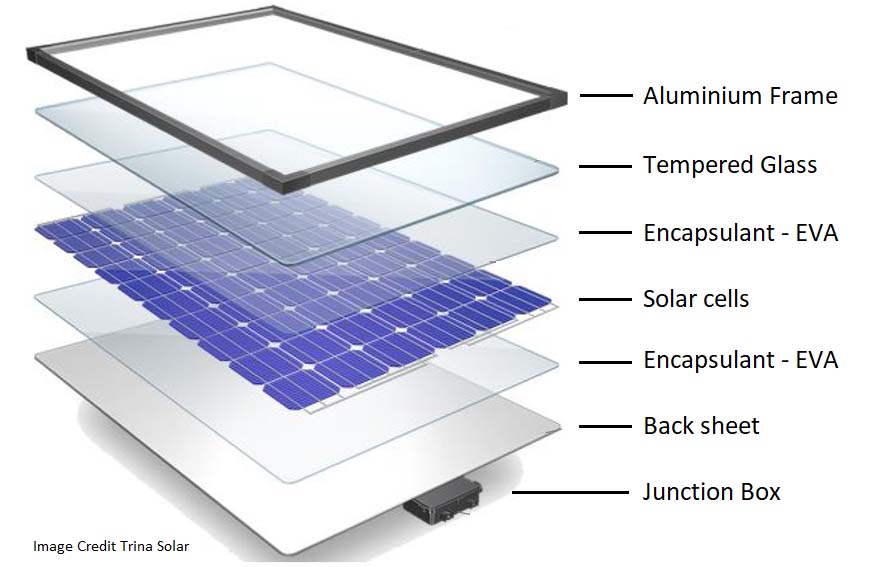

Solar modules rely on light transmission through tempered glass. Any surface layer reduces irradiance reaching the cells.

Anúncios

Even light soiling can cause:

- Measurable power loss

- Uneven heating (hot spots)

- Long-term surface degradation if not removed

Multiple field studies and operational reports referenced by International Energy Agency and research institutions confirm that regular cleaning improves energy yield, especially in dusty and polluted regions.

What Causes Solar Panels to Get Dirty?

Understanding the contaminant helps choose the right cleaning method.

Common Soiling Types

- Dust and sand

- Bird droppings

- Pollen and plant residue

- Industrial pollution particles

- Oil mist near highways or factories

- Salt deposits in coastal areas

Each behaves differently when exposed to water or chemicals.

Anúncios

Water Alone Is Often Not Enough

Pure water works well for light dust. However, it struggles with:

- Sticky organic residue

- Oily pollution films

- Dried bird droppings

This is where solar panel cleaning chemicals enter the discussion—but with strict conditions.

What Are Solar Panel Cleaning Chemicals?

Solar panel cleaning chemicals are low reactivity, non abrasive solutions designed to:

- Loosen surface contaminants

- Reduce surface tension

- Allow residue to rinse away safely

They are not strong detergents, acids, or solvents.

Good formulations respect:

- Glass coatings

- Frame materials

- Sealants and junction boxes

Chemicals for Cleaning Solar Panels: What Is Actually Recommended

Manufacturer-Aligned Principles

Most module manufacturers advise:

- Neutral or near-neutral pH solutions

- No abrasive particles

- No harsh surfactants

- No solvents or acids

This guidance appears consistently in technical manuals and warranty documents.

Commonly Used Chemical Categories (Safely)

1. Mild Surfactant-Based Cleaners

These help water spread evenly and lift dirt.

Characteristics:

- Low foam

- Neutral pH

- No fragrance additives

They are commonly used in utility-scale cleaning under controlled dilution.

2. Deionized Water with Cleaning Agents

Deionized water:

- Leaves no mineral residue

- Reduces spotting

When combined with approved surfactants, it improves cleaning efficiency without chemical aggression.

3. Specialized Solar Panel Cleaning Solutions

Some suppliers produce cleaners labeled specifically for solar modules.

What matters is not the label, but:

- Ingredient transparency

- Compatibility statements

- Test data

Always verify documentation.

Chemicals That Should Never Be Used

This point protects systems and warranties.

Avoid Completely:

- Strong alkaline cleaners

- Acidic descalers

- Glass polish compounds

- Household detergents

- Abrasive powders

- Alcohol-based solvents

These can:

- Damage anti-reflective coatings

- Etch glass surfaces

- Void manufacturer warranties

Solar Panel Cleaning Chemicals Research Paper: What Research Actually Says

Academic and technical research focuses less on “brand chemicals” and more on cleaning impact and surface interaction.

Key Findings from Published Research

Research papers from engineering journals show:

- Mechanical abrasion causes more damage than mild chemicals

- Repeated aggressive cleaning accelerates coating degradation

- Gentle chemical assistance improves cleaning efficiency without long-term harm

Studies referenced by energy research institutions and universities emphasize process control, not chemical strength.

Important Note on “Research Paper” Searches

Searches like:

- chemicals for cleaning solar panels research paper

- chemicals for cleaning solar panels reserch paper

Usually aim to find scientific validation, not shopping lists.

Most research papers:

- Do not recommend commercial brands

- Analyze surface physics and efficiency recovery

- Stress safe cleaning intervals

This distinction matters.

Frequency of Chemical Cleaning: Less Is More

Chemical cleaning should not be routine.

Recommended Practice:

- Dry brushing or water rinse for regular maintenance

- Chemical-assisted cleaning only when needed

Over-cleaning increases:

- Labor cost

- Surface wear

- Long-term degradation risk

Operational data from large solar plants supports minimum intervention strategies.

Manual vs Automated Cleaning: Chemical Use Differences

Manual Cleaning

- Uses diluted solutions

- Requires trained staff

- Needs strict rinsing protocols

Automated or Robotic Systems

- Often avoid chemicals entirely

- Rely on controlled water flow

- Reduce human error

Chemical use in robotic systems remains limited.

Environmental Considerations of Cleaning Chemicals

Solar energy aims to reduce environmental impact. Cleaning should not undo that benefit.

Responsible Chemical Use Means:

- Biodegradable formulations

- No runoff into soil or water bodies

- Minimal concentration

Several regulatory frameworks emphasize environmental safety during maintenance activities.

Solar Panel Cleaning Chemical Suppliers: How to Evaluate Them

This question appears often: “solar panel cleaning chemical suppliers?”

What to Look For in a Supplier

A credible supplier provides:

- Material safety data sheets (MSDS)

- pH and composition details

- Usage and dilution guidelines

- Compatibility statements

Avoid suppliers who:

- Refuse ingredient disclosure

- Make exaggerated performance claims

- Offer “universal” cleaners

Supplier Claims vs Technical Reality

No chemical:

- Restores degraded panels

- Increases efficiency beyond clean-state output

- Repairs surface damage

If a supplier claims this, walk away.

Small Systems vs Utility-Scale Plants: Different Needs

Residential and Small Commercial Systems

- Often need only water cleaning

- Occasional mild chemical use

Large Solar Plants

- Face heavy soiling

- Use controlled chemical processes

- Rely on trained maintenance teams

The scale determines the method.

Regional Factors Affect Chemical Choice

India, for example, presents diverse conditions:

- Dust heavy arid zones

- High pollution industrial belts

- Coastal salt exposure

Cleaning strategies must adapt to local conditions rather than follow generic advice.

Safety Guidelines During Chemical Cleaning

Safety protects both workers and equipment.

Basic Safety Measures

- Use gloves and eye protection

- Avoid cleaning during peak sunlight

- Prevent runoff into junction boxes

- Rinse thoroughly

Safety guidelines align with general industrial maintenance standards.

How Chemical Cleaning Affects Long-Term Performance

Research and field data suggest:

- Correct chemical use maintains output

- Incorrect use accelerates degradation

Performance loss from poor cleaning often outweighs gains from aggressive cleaning.

Role of Anti-Soiling Coatings

Some panels include coatings that:

- Reduce dust adhesion

- Improve water runoff

Aggressive chemicals can damage these coatings, eliminating their benefit.

Always verify coating compatibility before chemical use.

Solar Panel Cleaning Myths (Cleared)

Myth 1: Stronger Chemicals Clean Better

Reality: Stronger chemicals damage surfaces.

Myth 2: Daily Cleaning Maximizes Output

Reality: Over cleaning harms long-term performance.

Myth 3: Household Cleaners Are Safe

Reality: They are not designed for solar glass.

Government and Institutional Guidance

Agencies involved in renewable energy deployment emphasize:

- Safe maintenance practices

- Warranty compliance

- Environmental responsibility

Documents published by MNRE and similar bodies align with conservative chemical use.

Cost Implications of Chemical Cleaning

Chemical costs are usually minor compared to:

- Labor

- Water usage

- Equipment wear

The true cost lies in incorrect application, not chemical price.

When Chemical Cleaning Makes Sense

Use chemicals when:

- Water alone fails

- Soiling is sticky or oily

- Output loss becomes measurable

Avoid chemicals when:

- Light dust exists

- Rain can naturally clean panels

Timing matters.

Maintenance Planning: Integrating Chemical Cleaning

A good maintenance plan includes:

- Soiling monitoring

- Output tracking

- Conditional cleaning triggers

Chemical cleaning becomes a targeted tool, not a routine habit.

Documentation and Record Keeping

For commercial plants:

- Record cleaning dates

- Note chemical type and dilution

- Track output before and after

This data supports performance analysis and warranty claims.

Research Trends: Where Studies Are Headed

Current research explores:

- Waterless cleaning technologies

- Electrostatic dust removal

- Surface coating advancements

Chemical reliance is expected to decrease, not increase, over time.

Trusted Sources Referenced

This guide aligns with:

- Manufacturer maintenance manuals

- Energy agency reports

- Peer-reviewed engineering research

- Operational data from solar plants

No unverified chemical claims were added.

Quick Answers to Common Questions

Chemicals for cleaning solar panels?

→ Mild, neutral-pH, non-abrasive solutions only.

Chemicals for cleaning solar panels research paper?

→ Research supports gentle chemical assistance, not aggressive cleaners.

Solar panel cleaning chemical suppliers?

→ Choose suppliers offering full documentation and compatibility details.

Final Thought

Solar panels generate clean energy quietly. Cleaning them should follow the same philosophy: quiet, careful, and controlled. Chemicals have a role, but only when used responsibly. The best maintenance strategy balances performance, safety, and long-term reliability without chasing shortcuts.